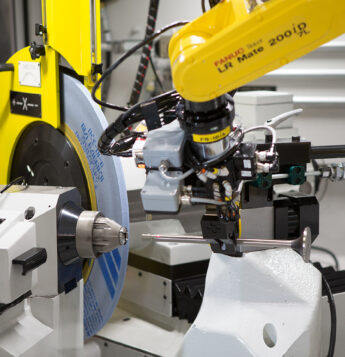

VSG-M3BL

Valve Seat Grinding Machine for Large Valves with Robot-loading

Key Points

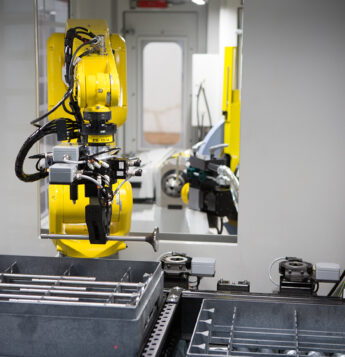

- Robot loading from trays

- Automatic tray handling system

- Suitable for larger valves

- Cycle Time – around 30 seconds depending on size and stock removal

- Loading system can be customised to suit other trays or pallets

Machine Features

- 3 servo axes + Robot

- 4500 RPM grinding spindle

- 600mm Ø or 500mm Ø grinding wheel

- Schmitt wheel balancer integrated into grinding spindle

- Static diamond dresser or 6000 rpm rotary disc dresser

- SMC or Festo pneumatics

- Multiple languages

- Kraft & Bauer fire suppression syste

- Optional programmable servo-controlled unloading system

- Optional High-pressure Wheel Cleaning System with servo control

Earlsdon VSG-M3BL Case Study

The rapid, powerful evolution of technology is encouraging more manufacturers to step into the era of automation.

Over the past two decades, automation has been transforming factory floors and helping manufacturers to solve issues, create opportunities, increase productivity, and more. Our VSG-M3BL automated grinding machine is one example of such automation.

Read our case study to discover how the VSG-M3BL machine helped one of our clients rejuvenate their production process:

What was the client looking for?

A bespoke, automated grinding machine that could integrate with their factory’s automation system. Specifically, our client wanted a machine that could:

- Be placed in an automated cell

- Apply the use of FANUC robots

- Machine large engine valves

- Perform automated loading and unloading to replace a manually loading machine

The client further requested that we tailor the machine by customising it to align with their production process.

The required customisations were as follow:

The result

Our talented, driven team of engineers assembled and built a machine tailored to all the requirements above. As requested, we delivered a flexible machine, featuring:

- Adaptable tooling that could work with parts of different sizes.

- An integrated FANUC robot that could stack, unstack, load and unload the machine

- A rapid automatic tool change over with automatic gripper change

Our automated solution helped the client free up operator time; as they were no longer spending valuable time loading and Unloading, they could invest more time on more high-level tasks.

Additionally, our machine helped the client reduce labour costs; cut cycle times, improve safety for operators.

Build your bespoke, optimised machine today

At e-tech, we are a world-leading manufacturer of high-performance machines. With a combination of knowledge, experience and state-of-the-art technology, we can adapt all of our machines to your bespoke needs.

Got an enquiry?

Fill in our form and we’ll get back to you as soon as possible.

Give us a call

on +44 (0) 24 7671 7023 and speak to our friendly support team.

Support & Spares

We will give you all of the assistance you need with maintenance, support and spares.