FR-4H1

4 Tonne Semi-Automatic Fillet Rolling Machine

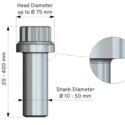

This is the latest and most powerful addition to our family of Fillet Rolling machines to suit almost every application. The FR-4H1 rolls the under-head radius of fasteners with up to 4-tonnes of force. It is designed for large fasteners up to M50 x 400 mm long.

This machine was developed for a customer in the aerospace industry. It has the potential to be used in wind, construction, defence, and other industries that require high-performance fasteners for safety critical applications.

Automated Part Loading

Automated part loading, that fits in with the needs of your production line, can be integrated into this machine. For example, previously we have developed and built a fully-integrated robotic-handling system for another one of our fillet rolling machines.

Key Points

- Rolling the under-head radius of fasteners with up to 4-tonnes of force

- 200 – 1000 parts per hour depending on size

- Precise, programmable rolling parameters with 100%

in-process checking - Specially-written user-friendly software in multiple languages

- Industry 4.0 compatible

- Fast changeover

- Safe, clean working

- Easy maintenance

- Customisable levels of automation to fit in with production line

Machine Features

- Free-standing machine designed to be at a comfortable height

for a seated operator - Automatic cycle initiated by two-hand safety switches

- Safety light curtain to protect the operator during the cycle

- Load cell to measure actual rolling force during each cycle and

to check that it is within programmed limits - Programmable control of rolling force, rpm & time

- Drive unit with inverter controlled spindle motor

- Allen Bradley or Siemens PLC control system with

6” touch-screen (HMI) - Integrated coolant tank, filter and pump

- Lockable tool tray

- 3G / Ethernet Modem for remote access

Got an enquiry?

Fill in our form and we’ll get back to you as soon as possible.

Give us a call

on +44 (0) 24 7671 7023 and speak to our friendly support team.

Support & Spares

We will give you all of the assistance you need with maintenance, support and spares.